Broer Bakkerijgrondstoffen invests in separate area for allergen free production

More and more people suffer from allergies and coeliac disease and sensitivity to peanuts and other nuts. Broer Bakkerijgrondstoffen decided on an increase in capacity to respond to this trend. The company invested in a separate production area for allergen free mixes, for the artisan baker and the industry. The dosing and weighing needs to be done very accurately. Conclusion after three months in operation: the automatic recipe machine that was purchased for this purpose appears to be extremely reliable.

CEO Jaap van Beek and operations manager Coen Veldhuis are enthusiastic about their recent investments.

"Allergen-free mixes will soon make up 40% of production."

In 2000, the management took Broer Bakkerij grondstoffen over from Unilever, after which they have gone from success to success. Van Beek: "There has been strong growth has since then. We have invested in people, machines and certifications. Our strategy was not only to improve quality, but also to become as flexible as possible." Recently, the company, which has a history of more than 95 years, was in turn partly taken over by Sonneveld Group BV from Papendrecht. This is a substantial step toward the aim of becoming a ‘one-stop shop’ supplier for the bakery sector. The company now has two separate powder production lines. The new line offers additional flexibility. “The risk of error is zero and we can supply really quickly. The software at the automatic recipe dispenser has a modular structure. If in the future we want to automate part of the process, then it can be implemented quickly. In addition, we now have the assurance of complete traceability on request. The composition of every batch is recorded.”

Basic Raw Materials

The producer from Waddinxveen specialises in two product groups. On the one hand, in raw materials for almond paste, confectionery paste, cookies and marzipan. On the other hand, in various ready-to-use powder mixes for the preparation of pastry goods and ice cream.Sales are predominantly in the Netherlands Van Beek explains that the powder recipes are a basic raw "The artisan pastry or ice-cream producers want to use their own fillings to create their own products with their special characteristics. In this way, they create a distinctive taste to distinguish themselves from the competition.”

New Production Area

The newly constructed space for the production of allergen-free mixes (without gluten and egg) was commissioned a few months ago. The investment in this relatively small space cost approximately 350,000 euros. The prospects are looking good. Veldhuis: "The allergen-free mixes, mainly yellow cream mixes and ice cream mixes will soon make up about 40 percent of our powder production." A part of the process is done manually. This covers the dosing, weighing and filling. The new mixer, with a capacity of 600 kilograms, equipped with metal detection and sieve screening, mixing a recipe in less than two minutes. The filling step takes place in big bags, and then laboratory staff take a sample for quality control purposes. The result is available within a day, following which it can be filled into bags ofinto bags of 7 to 25 kilograms.

"Here too we have built in flexibility. We could for example, fill bags of precisely 20.2 kilograms with the same facility”, explains Van Beek proudly.

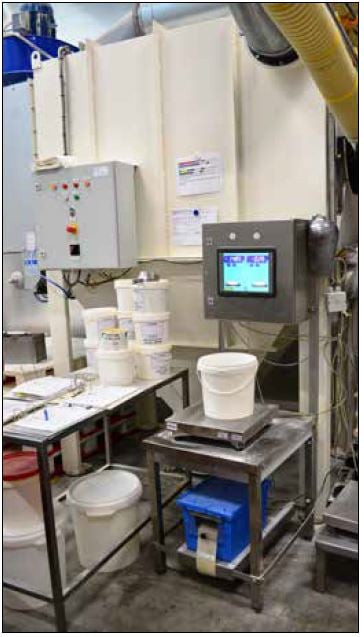

User-friendly Automatic Recipe Dispenser

Knowing what you have weighed and its quantity. That is the critical part of the process. This requirement has been fully met with the purchase of the automatic recipe dispenser and the customised software (BCS Batching Control System) from Penko Engineering. Inputting a recipe is very simple.

The operator sees on the screen the exact amount of raw materials, the scales to be used and the recipe for which they are intended. Each dosage is thus visible and is called off after weighing by the operator. Then the next raw material appears on the screen. A recipe must be fully dealt with before starting on the next recipe. This is to prevent mistakes. For weighing, there are two different weighing devices. A platform for weighing up to 30 kilos and a platform for weighing raw materials in grams up to 3 kilos. Veldhuis: "The unit is extremely user friendly. The operators find it completely understandable and each step is clearThe chance of mistakes is zero” The CEO explains, “Apart from the price, it was the simplicity of the solutions that attracted me to the presentation by Penko Engineering.