Crop Alliance has had experience with the weighing instruments of PENKO Engineering.

Out of the more than 30 weighing systems with different weighing capacities, recently eight instruments

have recently been replaced by the FLEX-2100 type. In

addition, the production line has been

expanded with two new ones.

Crop Alliance, onderdeel van TOP Oni-ons, houdt zich al meer dan 25 jaar bezig met de teelt, verwerking en export van uien. Het totale productaanbod van TOP Onions omvat alle soorten verse uien en, in verwerkte vorm, gebakken uitjes, uien-olie, zilveruitjes

en groenten (waaronder bloemkool). Voor veel producten heeft TOP Onions een gespecialiseerde produc-tiefaciliteit die is ondergebracht in een dochterbedrijf.

The Process

At CROP Alliance in Baarland (NL), the onions and vegetables arrive in bulk. Onions are unpacked (see picture 1) with vegetables in crates. Depending on the type of onion and its destination, a number of operations follow, such as washing, peeling, sorting,

checking, preser-ving and packing. Before the onions are packed after processing, visual inspection takes place, so that only good and undamaged onions are packed and deliver-ed. The preserved products are protected by a self-prepared liquid, vinegar

(acidic) or brine (salt). For the quality of the finished product, it is important to process it immediately after harvesting. The harvest of the onions takes place, depending on the weather, within 2 months, usually in August and September. This

not only means high pressure on the company, but also high demand on the equipment in use. A standstill literally means deterioration, and if the process stagnates, the quality of the product decreases as a result. That influences the entire process,

up to and including the finished product.Another aspect is food safety. In addition, traceability (tracking & tracing) is of utmost importance. That means knowing from which lot it comes from, how it was processed and where it went.

The Weighing Instrumentation

For filling the packages, CROP Alliance uses gross weighers. The processed vegetables and onions are weighed directly in the packages. The supply conveyor runs continuously, and when the package is on weight, an intermediate valve closes and the product

is temporarily collected (see picture 4). When applicable, the addition of protecting liquid takes place later on in the packaging process. The liquid is not part of the leaked out product, but it is important for its quality to be continuously completely

below the liquid level. The advantage to following a method of gross weighing is ensuring that the correct amount of product is always in the package.

TOP has had experience

with the weighing instruments of PENKO Engineering B.V. from Ede (NL) since the beginning. Out of the more than 30 weighing systems with different weighing capacities, eight instruments have recently been replaced by the FLEX-2100 type. In addition,

the production line has been expanded with two new ones. So now ten FLEX-2100's are in use. The choice for this instrument is based on the following reasons, namely:

TOP has had experience

with the weighing instruments of PENKO Engineering B.V. from Ede (NL) since the beginning. Out of the more than 30 weighing systems with different weighing capacities, eight instruments have recently been replaced by the FLEX-2100 type. In addition,

the production line has been expanded with two new ones. So now ten FLEX-2100's are in use. The choice for this instrument is based on the following reasons, namely:

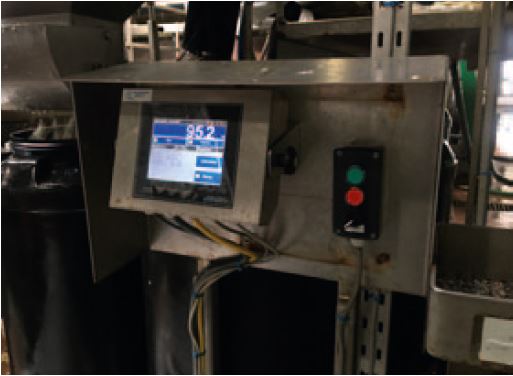

- simpler operation, thanks to the touch panel

- improved presentation of weight information by means of the larger display

- higher accuracy, with the measurement speed increased up to 1 600 measurements

- customised layout of the packaging information sticker which is printed directly after filling

Additionally, this type of instrument offers more communication facilities structures, including Ethernet. As a result of CROP Alliance’s quality assurance system, weighing data is centrally collected and classified, so that all information immediately

is available, from crop to customer.

In a number of cases, the weighing equipment is used for trade applications, when an inspection in accordance with the Metrology Law of the Netherlands is required. In addition, in order to ensure quality, CROP Alliance has a maintenance agreement with

PENKO. In addition to an annual check, PENKO will adequately correct faults when necessary. Fortunately, they rarely happen.

Download the Article